Finding your packaging solution means more than just figuring out what you need to do to protect your goods and store them on retailers’ shelves. It means figuring out how to design your exterior graphics and who to trust to deliver packaging you need whenever you have to reorder as well. You need to figure all of that out with the logistical projections that tell you how far in advance your orders need to be placed and the volumes your supplier can work with.

What Are Your Product Needs?

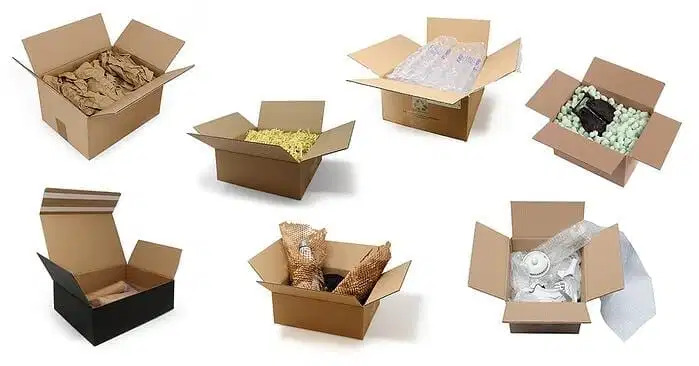

Understanding what you need your packaging to do for your product is the first step to narrowing down your choices. There is no set list of needs to consult, so get creative, but be specific. Some examples of common product needs can help, but you might also have unconventional needs that are still covered by the features of some types of packaging.

- Preserving freshness

- Maintaining spatial orientation

- Temperature sensitivity / frozen products

- Fragile

For a product that needs all four of these features, you would probably want to avoid bulk bags that are common for many frozen foods. A common approach to this solution is to use an air-pack bag inside a box with a clear up/down display orientation, but that’s just one example. More and more, environmentally friendly companies are solving the issue with stand up pouches and other choices that minimize the materials needed to construct their packaging.

How Will You Customer Interact With This Product

The other big consideration you need to make is how the customer will approach and interact with your product based on the packaging. If you protect the product well and meet your basic needs from the list you made, you still need to find the approach that meets your customers’ expectations for ease of use, environmental friendliness, and general appeal. That means you need to consider features like printability and customizability to carry your branding.

It also means you need to learn to answer questions like what does MOQ stand for? The short answer is that the MOQ is the minimum quantity you need to order to make a production run worthwhile for your provider when you order custom packaging. The key to creating the packaging that works best for your business is finding a supplier who can deliver the custom design you need to meet all your product needs while providing the customer with the experience you want them to have, without requiring you to order more packaging than you need.

Set Your Business Up For Success

It’s hard to overestimate the impact of marketing in situ. You can invest in ads, billboards, and digital marketing brilliantly, but at the end of the day, the sale is often made by the impact your product has on the customer when it’s encountered on a shelf. That can be true for customers who know your brand from those other marketing efforts as well as those encountering it for the first time.

When you understand the packaging design that you need and the minimum quantity requirements that are attainable for your business, it’s a lot easier to assess each packaging printing company you encounter, because you have a clear list of requirements for them to meet. Start building your list.