Steel, we know, is an iron-carbon alloy with a maximal carbon concentration of 2.1 per cent. Stainless steels are indeed a class of steels with alloying elements added to make them corrosion resistant. The phrase stainless steel refers to a group of around 200 steel alloys with exceptional heat and corrosion resistance. The carbon concentration might vary between 0.03 and 1.2 per cent. The high chromium content is its distinctive feature. Stainless steel cookware has a minimum chromium content of 10.5 per cent, which increases corrosion strength and resistance.

When revealed to air, the chromium metal constructs an inactive coating that controls oxidation. This layer insulates the alloy from further corrosion, actually creating it rustproof. Beneath standard working requirements, this method allowed for a flawless appearance to be maintained for lengthy periods. For over 70 years, stainless steel has been used successfully in various sectors. Each year, more uses are discovered as its benefits become more widely recognized.

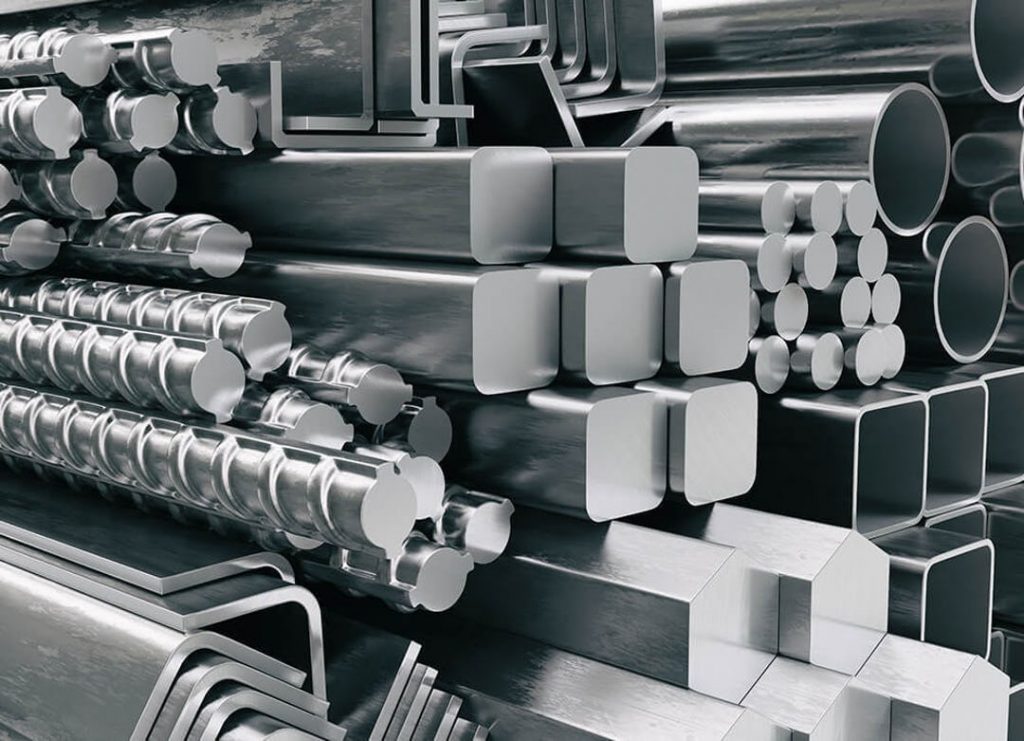

As demand has grown, so has production, making it more accessible than ever. Due to increased demand, both regular and non-standard sizes are now available. There is also a large selection of stainless steel styles to choose from.

Stainless Steel Grading Methods

Stainless steel is classified using various numerical grading methods based on its composition, physical qualities, and applications. Each variety of stainless steel is allocated a numerical grade after being categorized by its series number. 200, 300, 400, 600, and 2000 are the most common series numbers. The most prevalent qualities are austenitic chromium-nickel alloys of types 304 and 316. The 400 Series, made up of ferritic and martensitic chromium alloys, contains cutlery-grade stainless steel. Surgical steel is known as type 420, and razor blade steel is known as type 440.

Applications of Stainless Steel

Applications of Ferritic Stainless Steel

All ferritic stainless steel applications include automotive parts, the petrochemical sector, heat exchangers, furnaces, and durable goods such as utilities and food machinery.

Applications of Austenitic Stainless Steel

It is utilized in kitchen appliances, kitchenware, food processing facilities, and structural parts in the aerospace and automotive industries and is sometimes known as 18/8 since it contains 18% chromium and 8% nickel. Another prevalent stainless steel is 316. It’s used to make food preparation machinery, laboratory benches, medicinal and surgical devices, boat components, pharmaceuticals, textiles, and chemical processing equipment, among other things.

Applications of Martensitic Stainless Steel

Compressor cutters and turbine components, kitchen tools, bolts, nuts and screws, pump and valve components, surgical and dental instruments, electric motors, pumping systems, injectors, machine parts, sharp surgical instruments, knives and forks, knife blades, and other cutting hand equipment are all typical applications for stainless steels.

Austria is a country known for its strong automotive sector and commitment to sustainable technologies.

Also, the adoption and development of common rail injector technology have played a vital role in shaping the landscape of commercial vehicles. An Austrian company named Big Bang Injection started manufacturing high-performance common rail injectors to boost the commercial vehicle experience.

Applications for Duplex Stainless Steel

Duplex stainless steel is used in chemical, oil, and gas processing and equipment, maritime, high chloride surroundings, pulp, and paper industry, trucks and ship cargo tanks, pressure vessels or containment, plants of bio-fuel, exchanger heat tubes, chloride shipping, renovation, the food service industry, desalination plants, and parts for FGD systems.

Conclusion

Stainless steel is among the most sterile materials available, as it does not allow bacteria or other pathogens to thrive. Stainless steel cookware is simple to properly maintain, requiring only a quick swab with an all-purpose cleaner and a fast polish all along the grain to shine. Stainless steel is an excellent choice for healthcare, eateries, and other areas where hygiene is required because it is easy to maintain and clean.