If you work in the aggregate sector, you’re probably aware of the importance of having the correct screen for the job. There are numerous varieties of screen materials available, each with its own set of benefits and drawbacks. It’s critical to analyze your demands and applications before selecting replacement screening material. Although woven wire cloth is the most often used screening material in the industry, form wire screens can be more effective in some situations.

Here in this blog, you will see the difference or similarities between two different wire screens. There is brief information on both woven wire cloth screens and shape wire screens. You can get to know about these two products and can choose according to the requirements.

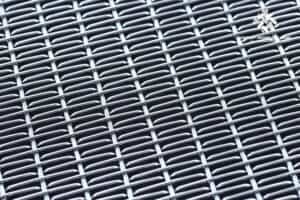

Woven Wire Cloth Screens

Woven wire screens are one of the most extensively used screening methods. It’s employed in every stage of the screening process to screen almost any product that’s been reduced to a specific size gradation. It is utilized in both wet and dry techniques for initial scalping, sizing, and dewatering.

Woven wire cloth is arguably the most often used screening medium because it is inexpensive, provides excellent screen accuracy, and applies to most screening applications. Woven wire screens are available in three-wire types: high carbon, oil tempered, and stainless steel, and manufacturers can build the broadest and longest screens on the market.

Furthermore, all of the Manufacturers’ woven wire cloth screens are individually checked for fit and accuracy, and they are the most cost-effective screens available. On the other hand, woven wire cloth isn’t always the best choice for screening, especially when blinding and pegging are a concern. Shape wire screens are the best option in these cases.

Shape Wire Screens

Shape wire screens are non-woven wire screens that provide distinct advantages and solutions. Shape wire screens are a good alternative for screening aggregates that frequently cause blinding and pegging since each wire functions independently because they are not woven.

Pegging occurs when particles of similar size enter an aperture and pass through it partially but become “pegged” in the opening when a critical dimension is too great. The particle cannot pass through or remove itself from the beginning, effectively sealing it and lowering the number of apertures available to other particles.

Blinding is a phenomenon in which particles stick to the screen’s surface, which is frequently caused by dampness. When one particle sticks to it, other sticks to it, and so on, creating an exponential sequence that eventually bridges the apertures and causes blindness.

The form wire screen is made of piano wire, which allows each wire to vibrate separately. This makes it easier for materials to travel through and prevents aggregate from clinging to the individual wires. Furthermore, the form wire is available in three different configurations, allowing you to select the ideal screen for almost any application.

Conclusion

Now you have got to know what is what. But there is much about it, and you can get all this information from the wire screens manufacturers. They can explain the precise applications, benefits, and usage in practical situations. When you know about the exact properties that are reliable and perfectly go with your needs, they will be accessible in the purchasing process. By buying the right product, the further procedures will be suitable and perfect too.